Wind Turbine

Conversion of Energy

Wind turbines convert the kinetic energy of moving air into electricity. The wind rotates the rotor blades, which are then connected via a shaft to a generator that produces electrical energy.

Growth and Capacity

Since 2000, wind power has seen substantial growth due to advancements in research and development, supportive policies, and decreasing costs. Global installed wind generation capacity surged from 7.5 GW in 1997 to approximately 733 GW by 2018, as reported by IRENA.

Cost Trends

The cost of wind power has significantly decreased over the years. Between 2010 and 2020, the global weighted-average levelized cost of electricity (LCOE) for onshore wind fell by 56%, from USD 0.089/kWh to USD 0.039/kWh.

Technological Advancements

Wind turbine capacities have expanded considerably. In 1985, turbines had a capacity of 0.05 MW with a 15-meter rotor diameter. Today’s turbines typically have capacities of 3-4 MW for onshore and 8-12 MW for offshore installations

Understanding Turbine Mechanics: Components and Power Transmission

Explore the key elements of turbine mechanics and how they contribute to efficient power transmission:

-

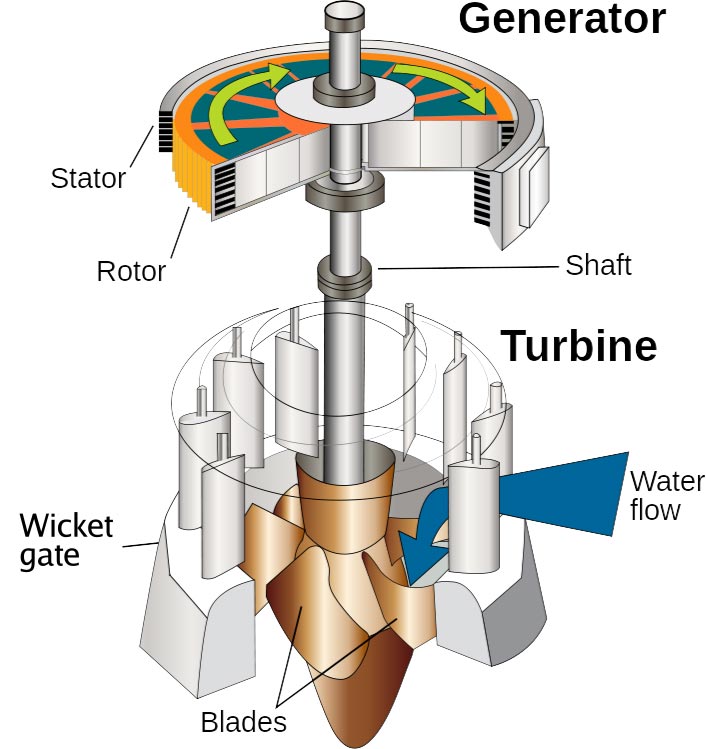

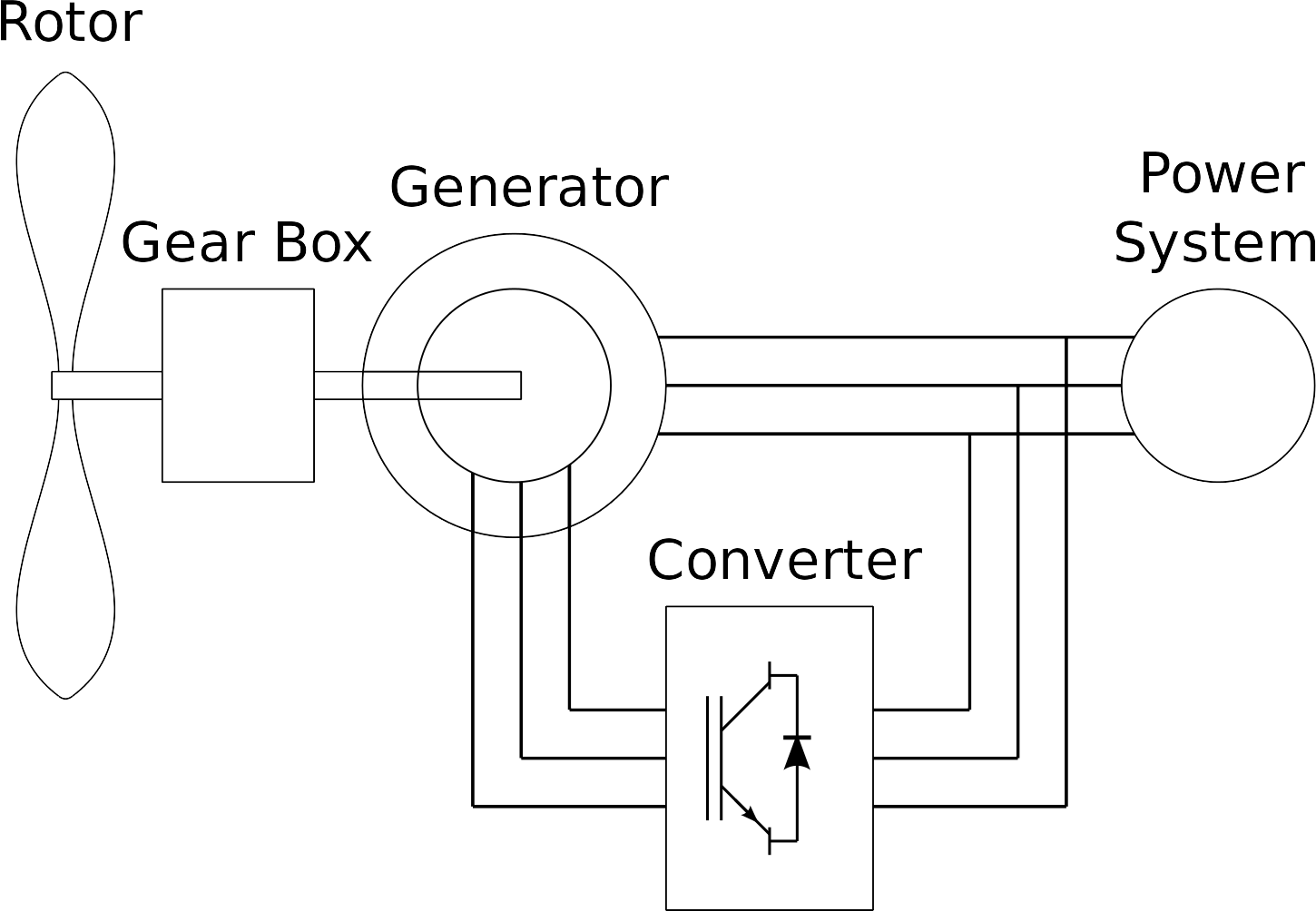

Turbine Components: Key parts include rotor blades, the rotor hub area, and connecting elements that work together to capture and convert wind energy.

-

Drivetrain System: Comprises the rotating mass of the turbine, a slow shaft, a gearbox, a fast shaft, and the generator. This system is essential for transferring and increasing rotational speed.

-

Mechanical to Electrical Conversion: The drivetrain transmits mechanical power from the turbine to the generator, which then converts it into electrical power.

-

Efficiency Considerations: Understanding these components and their functions is vital for optimizing turbine performance and ensuring efficient energy production.

A schematic representation of a turbine